Using Terrazzo In Your San Francisco Home

From venetians to victorians, terrazzo tile has been in and out of style more times than San Francisco has foggy days and bad press on Fox-aganda “news”.

What is Terrazzo?

Terrazzo tile is a low-maintenance material that is:

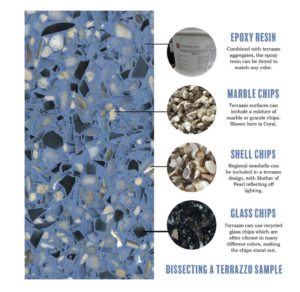

- A composite made from types of stone such as marble, granite, quartz, glass, and more…

- Held together with resin or concrete.

- Particularly popular in the 1920s, 1980s, and now!

- The ‘it’ material of 2023.

- Low-maintenance!

Terrazzo Doesn’t Have To Be Terrible

You may remember this stuff from the floors of a school or government building conceived sometime in the 70s. It’s a very hard, stone-like material, with those telltale chips embedded in the matrix.

Terrazzo actually has a very long history — examples have been found as far back as 9,000 B.C. It’s currently viewed as a bit of a luxury finish, but modern terrazzo was actually created as a budget-friendly, DIY material.

Venetian construction workers, looking for a low-cost way to surface the terraces surrounding their homes, set broken bits of marble into clay, and then ground down the resulting surface with stones until it was smooth. The name they gave this finish — terrazzo — is also the Italian word for terrace.

While credit is traditionally given to the Italians, as it is commonly recognized that terrazzo was invented by the Venetians, archaeologists have found evidence of such floors in ruins in Turkey dating back 10,000 years ago.

Fast forward to today, and a majority of installations are epoxy-based. Terrazzo is also related to the technique seminato (meaning seed). For this technique, workers would toss large marble chips into the wet cement that was later ground and polished.

Together, these two methods create the generic form of terrazzo that involve pieces of stone that re-bonded to a cement bed.

Why Choose Terrazzo?

There are virtually unlimited color and material options – fragments could be anything from marble to quartz, glass and metal – and it is extremely hard-wearing. Plus, given that it is made using offcuts, terrazzo is also a sustainable decorating option.

Where Can You Use It?

Once sealed to ensure water resistance, it can be applied to any interior wall or floor, including kitchens and bathrooms. Terrazzo retains warmth effectively, so it is a great choice for underfloor heating. In addition, it can be poured into any moulds, so it is now being used to create furniture and homeware.

Terrazzo Across San Francisco

Is it easy to maintain?

A simple steam mop or nylon scrubbing brush is all that is needed to clean it. Poured terrazzo, however, is more prone to cracking than slabs. To restore it, the floor will need to be re-ground and re-polished by a specialist.

What are the latest innovations?

These days terrazzo is made with chips of marble, quartz, granite, or even glass set into a matrix of concrete or epoxy resin. The chips can actually be quite large, and the matrix and the aggregate can be almost any color you can imagine, which makes for a myriad of design possibilities.

Resin is now being used as well as the traditional cement to produce terrazzo. It’s a more expensive option, but has a smoother finish and is also highly resistant to scratches and cracking.

You’d be amazed how many homes in San Francisco, from new to old, embrace the use of this timeless material throughout the home. Hit the button below if you’d love to see some in person!